Sheet metal processing machines for the food industry

In the food industry, sheet metal processing machines are not just tools; they are the key to precise and hygienically flawless sheet metal forming. Our special machines set standards in precision, reduce manual labor, and ensure smooth processing – from stainless steel to high-alloy steel sheets.

2-roll round bending machines

Our 2-roll round bending machine RBAZ is the ideal solution for precise and fast pipe manufacturing – whether manual or fully automatic. With intelligent PLC control, robust rolls, and intuitive operation, it ensures the highest bending quality and productive processes. Discover now and optimize your production!

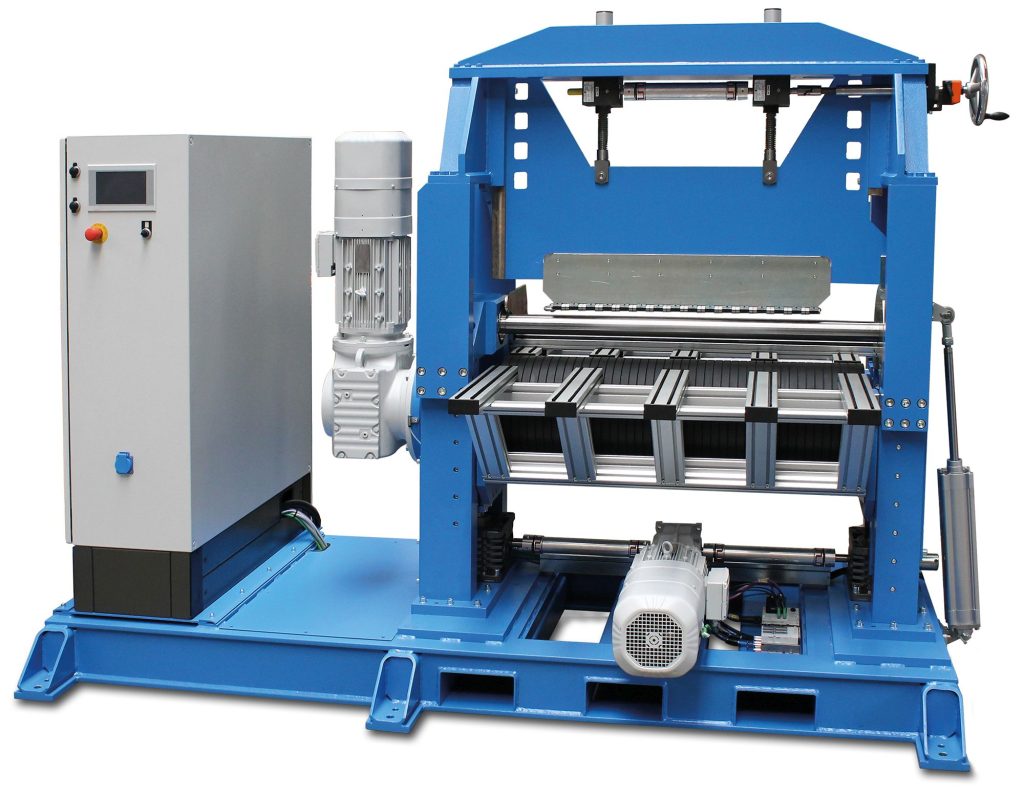

4-roll round bending machines

Our 4-roll round bending machines enable precise, repeatable bending of sheets – ideal for industrial continuous operation. Thanks to modern PLC control, touchscreen operation, and infinitely adjustable drives, the machines integrate seamlessly into automated production lines. Discover now and make your production processes more efficient and future-proof!

3-roll round bending machines

Our 3-roll round bending machines from the RM and RME series offer ideal solutions for manual and motorized bending work in sheet metal processing. Whether for single or series production – thanks to robust construction, flexible settings, and optional accessories, you achieve consistently precise results.

Beading and flanging machines

Our beading and flanging machines allow for exact, repeatable results in the processing of pipes, sheets, and complex components. Whether manual or motorized, mobile or for industrial continuous operation – we offer the right solution for crafts and industry. Discover now and make your production processes more efficient!

Clean cuts, safe processing: This makes our machines unique

Our sheet metal processing machines are essential for the food industry, as they enable hygienic, safe, and precise processing of stainless steel. In this industry, particularly strict regulations apply regarding hygiene and product safety – residues or contamination can not only affect quality but also violate legal requirements.

Benefits for your production

- Precision: High-quality sensors and modern control technology enable precise results and high repeat accuracy in every step of work.

- Durability: High-quality stainless steel components and processing guarantee a long service life even in demanding production environments.

- User-friendliness: Intuitive user interfaces and automatic calibration reduce errors and facilitate operation.

- Minimal downtime: Robust construction and ease of maintenance ensure continuous production readiness.

- Material efficiency: Accurate cutting and forming processes minimize waste and optimize material usage.

- High production speed: Automated processes reduce processing times and enable higher output.

Contact

Do you have any questions or would you like to receive a consultation or offer directly? Then feel free to inquire through our contact form.