Special and customized machines from Peter Prinzing

Overview of our special machines

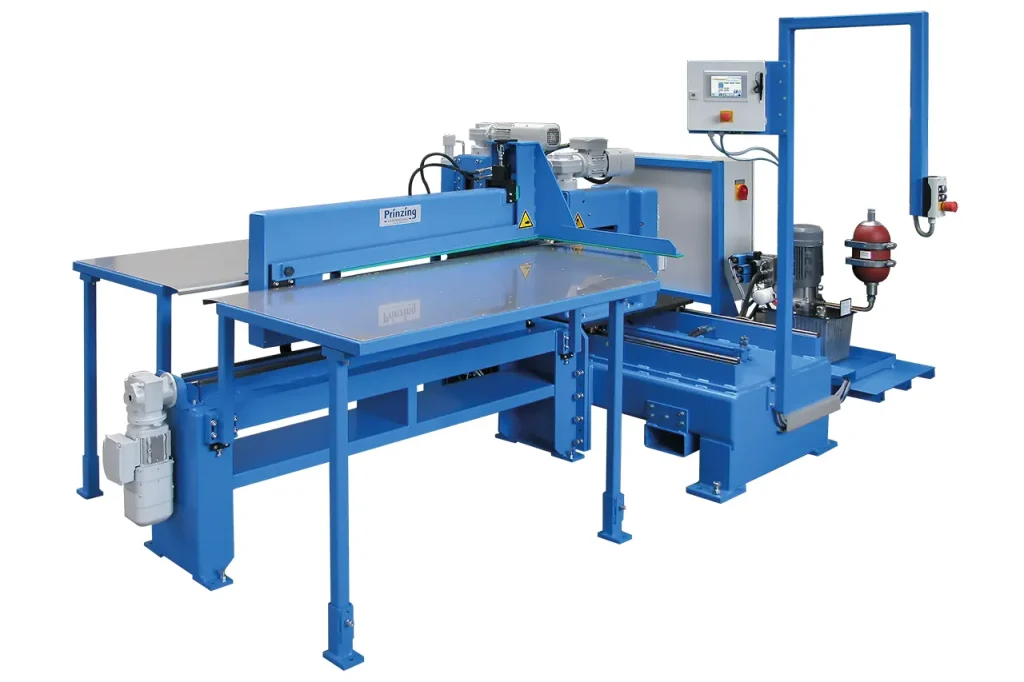

Conical bending machines RK and RZK

The RK and RZK bending machines offer a highly precise way to bend conical products using NC control. Depending on the application, either two or four rollers are used, which are controlled by a PLC. The resulting high repeat accuracy simplifies subsequent work on a longitudinal seam welding machine and enables an industrial standard. The feed is provided by a continuously variable brake motor.

Round flanging machine bea

The flanging machine BEA is perfect for producing round-flanged pipe ends. The pipe is securely clamped while the tool rotates. This approach not only achieves high quality but also excellent repeat accuracy. The method is suitable for both internal and external flanging.

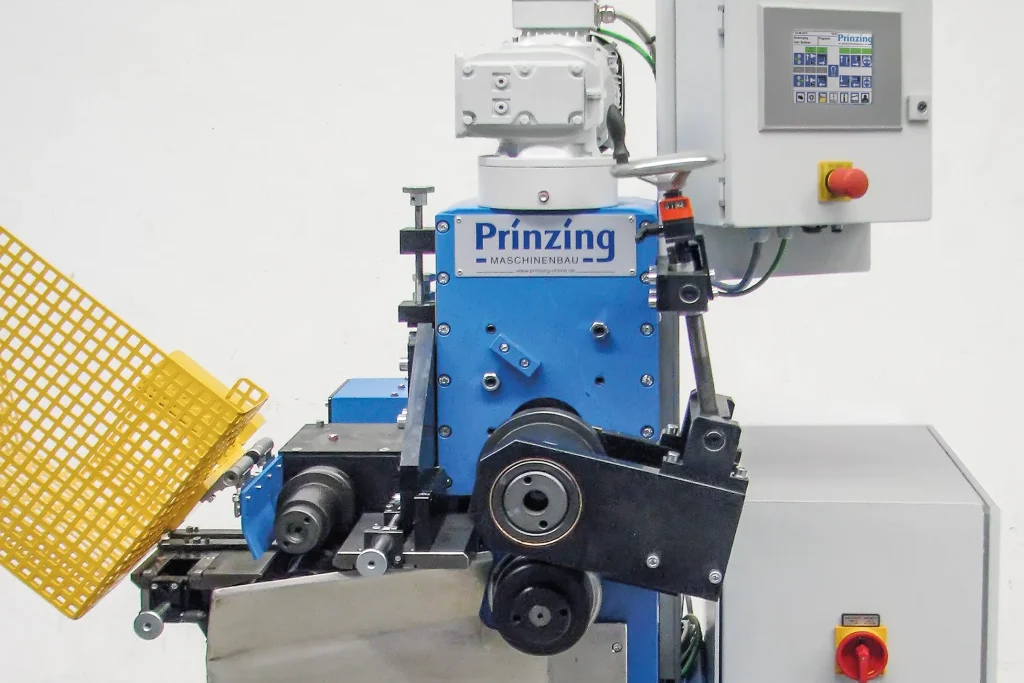

Flange machine FME

The flange machine FME offers a convenient way to manufacture flanges in any size. The shaping technology of the FME eliminates the need for laborious welding work. 90° flanges can be produced with excellent quality on this machine. The FME can also meet demands where conventional flanging machines reach their limits, such as flange heights up to 50mm.

The models FME 4 and FME 8 process sheet thicknesses of up to 4 mm and 8 mm respectively, as well as pipe diameters of up to 1,200 mm and 1,500 mm respectively. The maximum flange heights are 25 mm for the FME 4 and 50 mm for the FME 8. Both have a flanging unit with roller-bearing working shafts, a motor-adjustable top shaft, and a continuously variable brake motor. Control is via a touchscreen with a program memory for up to 200 programs. For precise pipe processing, an adjustable pipe guide, a pneumatic pipe counterholder, and a pipe holder as well as a base frame with motorized pipe length adjustment are integrated. The specifications for sheet thickness refer to material with a tensile strength of 400 N/mm² and a yield strength of 250 N/mm².

Strapping machine SME-S

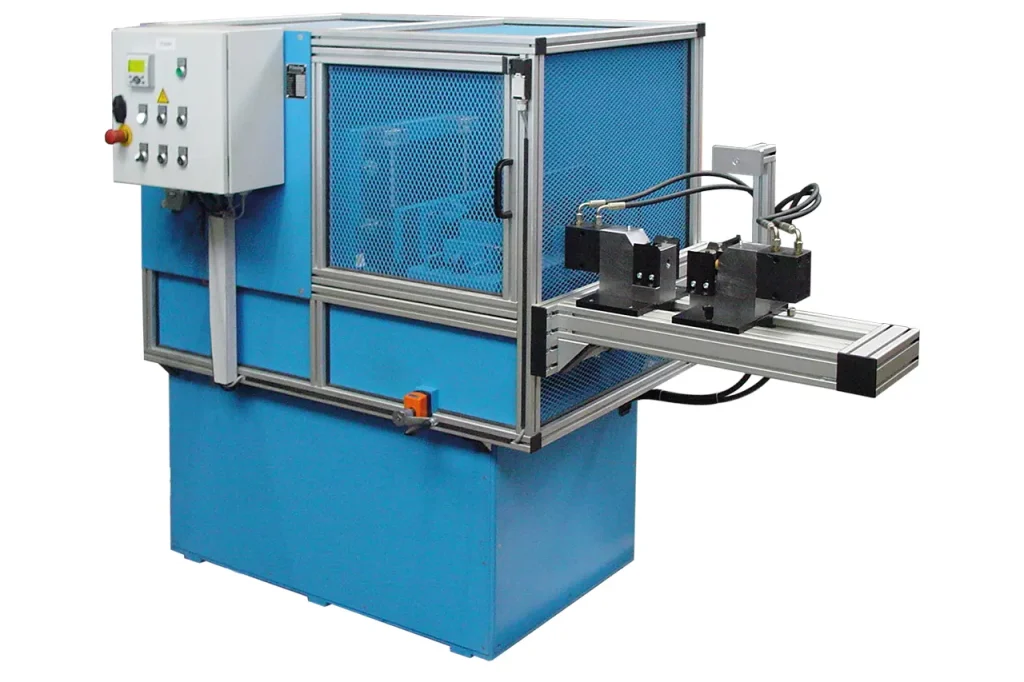

Edge former KFE

Pipes with specially cut ends cannot be processed with a conventional flanging machine. For these requirements, the edge former KFE is the right machine. The machine has a hydraulic forming slider equipped with a specially adapted die for the shape of the pipe. A typical application for the edge former is the production of pipes for T-pieces.

The example size KFE 1 is suitable for pipe diameters from 80 to 320 mm. The maximum pipe length is 250 mm. The flange height is between 4 and 10 mm. In the case of steel sheets, a maximum sheet thickness of 1.2 mm can be processed, while for stainless steel 1.4301, the maximum sheet thickness is 0.8 mm.

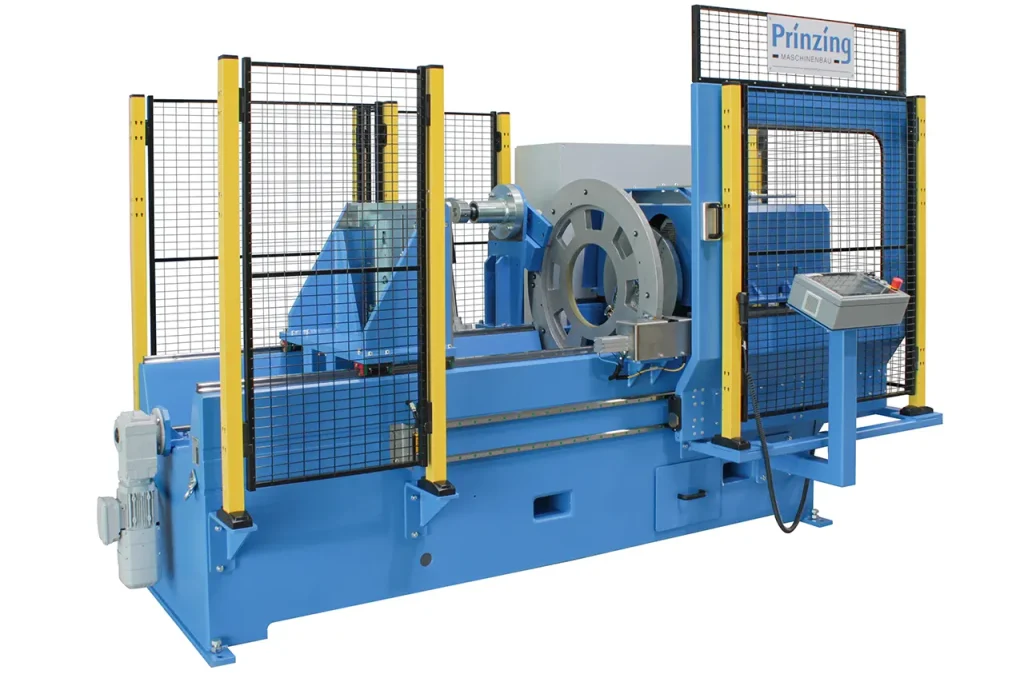

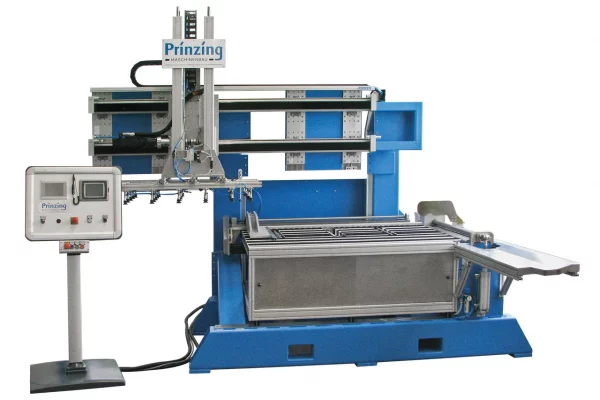

Circle cutting and profiling machine KSMR

The KSMR is a system that has two workstations. With the combination of a circle shear and a crimping device, sheet rings can be produced and profiled with just one clamping. The system can be programmed via a touchscreen.

The system includes a circle shear station and a crimping device, both with continuously variable motor-driven feed. A stable base frame and a lateral slide with linear guidance ensure precise movement sequences of both workstations. The equipment is complemented by a motor-adjustable guide arch, an integrated sheet centering, and a support table. Control is conveniently done via a programmable touchscreen, while a safety fence with a light barrier provides the necessary protection.