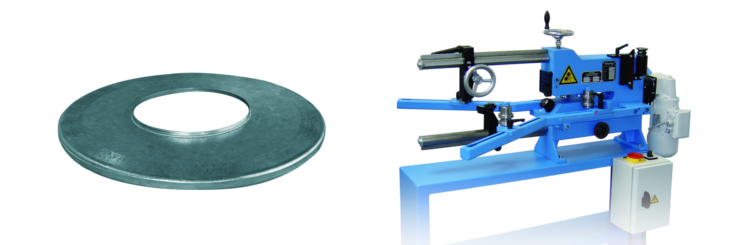

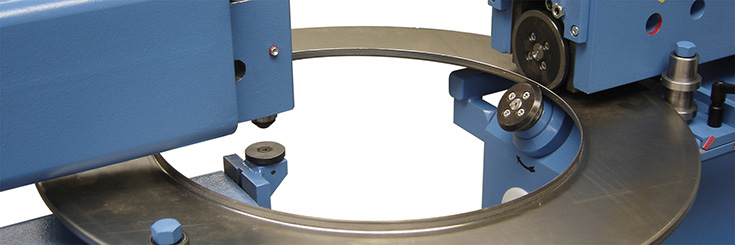

The use of the circular shear KS is to cut tubes out of steel, stainless steel and other materials. It is possible to machine a sheet thickness up to max. 2,0 mm. The basic function can be extended with a beading device for internal and external shelves on a tube.

In general we differ in manual and motor driven machines. At the KSE 12, the upper and lower cutter will be driven. The circular shears 8 - 12 are available as well as in manual (KS) or in motor driven design (KSE).

A lightweight but also solid construction is making this machine transportable. Because of that this machine is also applicable for building sites.

Standard equipment:

- 1 pair of cutting rolls

- 1 elastic carrier plate

- operation tools

- guide bars out of stainless steel

- manual diameter adjustment with millimeter display

- manual infeed of the centering spike (if you have an electric driven machine, the sheet can also be clamped hydraulic or pneumatic)

- changeable clamping plates

- adjustment of the cutter clearance by screw socket and scale

Options:

- single-, two-stage- or infinitely variable drive

- device for internal- external flange

|

Example sizes KS 8-10 and KSE 10-12

|

|

|||

|

Model

|

KS 8

|

KS 10

|

KSE 10

|

KSE 12

|

|

Sheet thickness* max (mm)

|

1

|

1,5

|

1,5

|

2

|

|

Round blank diameter max (mm)

|

1000

|

1500

|

1000

|

1000

|

|

Throat depth (mm)

|

280

|

280

|

280

|

280

|

|

* The sheet thickness refers to a material with a tensile strenght of 400 N/mm² and an elastic limit of 250 N/mm²!

|

||||

|

|

||||