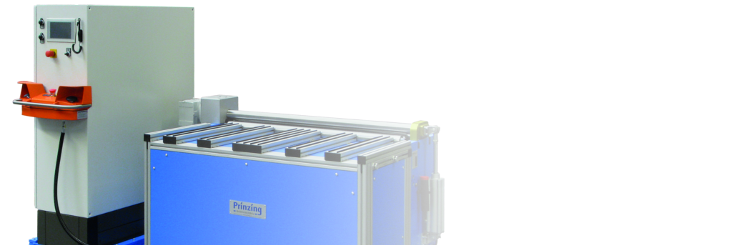

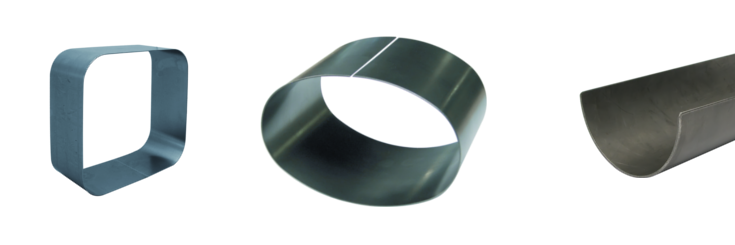

The RBB is the entry model into the world of bending of tubes and forms. Through the four-roll technology and SPS which is enabling the pre- or re-bending, sheet metal tubes can be produced which can be welded on longitudinal seam welding machine with a laser or WIG.

Infinitely variable feed motors provide the pre-bending and the bending angle. The plate thickness is adjusted by pneumatic cylinders. The lateral stop for pre-bending is free-standing. Control panel with PLC control and touch screen.

Bending rolls are are out of high strength material and can be hardened and ground on customers demand.

|

Example sizes RBB 42-70

|

|

|

||

|

Modell

|

RBB 42

|

RBB 52

|

RBB 60

|

RBB 70

|

|

Effective length max [mm]

|

530

|

1030

|

1030

|

1030

|

|

Sheet thickness* max [mm]

|

1

|

1,2

|

1,5

|

1,8

|

|

Diameter upper roll [mm]

|

42

|

52

|

60

|

70

|

|

|

|

|

|

|

|

Modell

|

RBB 85

|

RBB 100

|

RBB 120

|

|

|

Effective length max [mm]

|

1030

|

1530

|

1030

|

|

|

Sheet thickness* max [mm]

|

2,5

|

2,4

|

4,5

|

|

|

Diameter upper roll [mm]

|

85

|

100

|

120

|

|

|

* The sheet thickness refers to a material with a tensile strenght of 400 N/mm² and an elastic limit of 250 N/mm²!

|

||||

|

|

||||