Whether inside, outside or center fold - this machine is the ideal solution for quick closing of various tube seams.

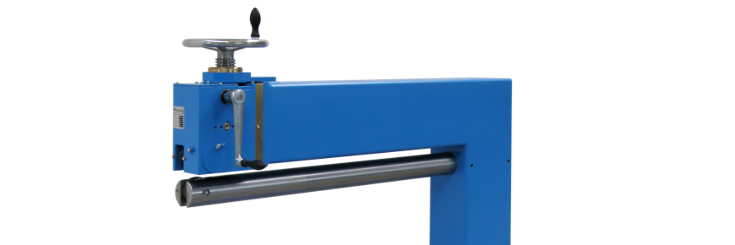

The machine has a rugget and sturdy steel construction. All drive elements in the pressing button have roller bearings and easily adjustable via a hand wheel. The infeed of the upper pressing roll is manually via a spindle. Flat guides are backlash and designed re- adjustable.

By default, a round guide pin belongs to the machine. On request, a square mandrel can be made.

The pressing rolls are made of hardened steel. The standard model includes a set of pressing rolls, which you can decide between inside-, middle- or outside fold.

The guide pin and the folding rolls can be quickly and easily replaced.

The drive of the machine is done manually through a crank or a single-stage electric motor.

The smaller machines (RFZH 4 + RFZH 8) can be fixed by a wall bracket, the larger (RFZH 12 - RFZ 15) are mounted on a sub frame.

Special Equipment:

- Sub frame for RFZH 4 and 8 RFZH

- Pneumatic infeed for RFZ 12 and 15 RFZ

|

Example sizes RFZH 4-12 und RFZ 12-15 |

|

|

|

||

| Model | RFZH 4 | RFZH 8 | RFZH 12 | RFZ 12 | RFZ 15 |

| Sheet thickness* [mm] | 0,4 | 0,8 | 1,2 | 1,2 | 1,5 |

| Mandrel length [mm] | 520 | 1020 | 1020 | 1020 | 1530 |

| Tube length max [mm] | 1040 | 2040 | 2040 | 2040 | 3060 |

| Mandrel diameter [mm] | 35 | 55 | 90 | 90 | 150 |