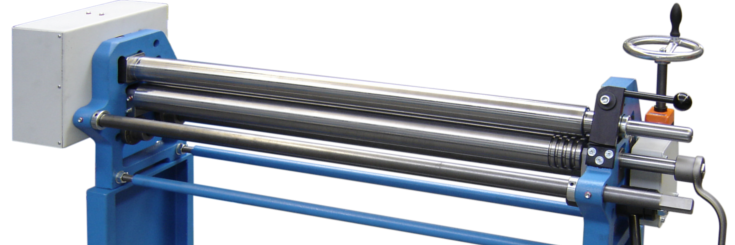

The three-roller bending machine is rounding by the electrically driven upper and lower roll. The single-stage motor is operated via a double foot switch for forward- and backward move.

The roll diameter ranges from 20 mm to 120 mm and the length of just over 200 mm to 2.5 m.

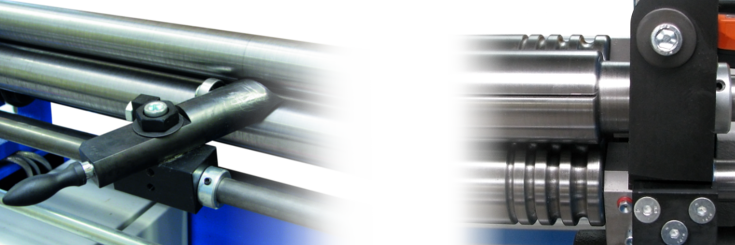

The rollers are arranged asymmetrically. Quick and easy removal of the finished tubes is facilitated by the forward swing-top roll. Depending on the dimension, the rolls have a spherical shape.

Standard Features:

- Upper roll swinging to the front by quick release

- Quick adjustment of the bottom roll

- Screw adjustment of the back roll with mech. display

- Drive by gear brake motor

- Sub frame

Special equipment:

- Switchable or infinitely variable motor drive

- Three roller drive

- Folding slot in the upper roll

- Wire core groove

- Special rolls (hardened, tempered, ground, rubberized)

- Lateral stop for conical rounding

- Support plate with lateral stop

- 4th roll as pre bending roll with SPS and automatic program sequence

- Motor infeed of the back roll

|

Example sizes RME 20-120

|

|

|

|

||

|

Model

|

RME 20

|

RME30

|

RME 42

|

RME 52

|

RME 60

|

|

Effective length max [mm]

|

330

|

530

|

1030

|

1030

|

1530

|

|

Sheet thickness* max [mm]

|

0,5

|

0,6

|

0,6

|

1,2

|

0,8

|

|

Diameter upper rolls [mm]

|

20

|

30

|

42

|

52

|

60

|

|

|

|

|

|

|

|

|

Model

|

RME 70

|

RME 85

|

RME 100

|

RME 120

|

|

|

Effective length max [mm]

|

2030

|

2030

|

2030

|

2530

|

|

|

Sheet thickness* max [mm]

|

0,8

|

1,2

|

1,8

|

1,5

|

|

|

Diameter upper rolls [mm]

|

70

|

85

|

100

|

120

|

|

|

|

|

|

|

|

|

|

* The sheet thickness refers to a material with a tensile strenght of 400 N/mm² and an elastic limit of 250 N/mm²!

|

|

||||

|

|

|

||||