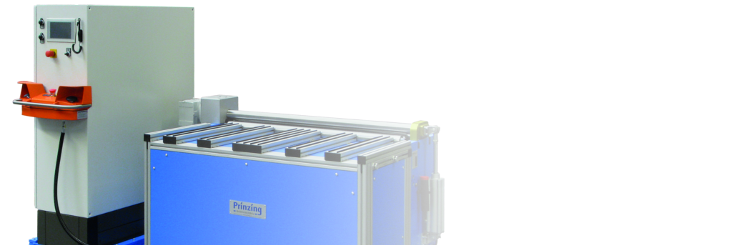

The round bending machine (RBA) is our high-end product in the field of tube manufacturing. Accuracy and speed, these features the RBA combines and therefore fits in any modern tube manufacturing. Whether manual loading and unloading or complete integration in a fully automatic tube production line, both scenarios can be covered by the RBA. By the modern SPS not only programs can be stored but also communication with other systems can be built.

The RBA is in a four-roll design. The rolls are positioned by a infinitely variable motor. The motors are doing the feeding, bending angle and sheet tension. Control panel with SPS-control and touch screen for setup- and automatic sequence.

Features of the machine:

- Four roll design with high-strength rolls

- Roll positioning motor driven, infinitely variable

- Sheet metal stop and bearing cap pneumatically controlled

- SPS-control of the machine with touch-screen control

- Program memory, power failure, with password protection

- Individual program settings for various tube profiles

- Compact and service-friendly design of the machine

|

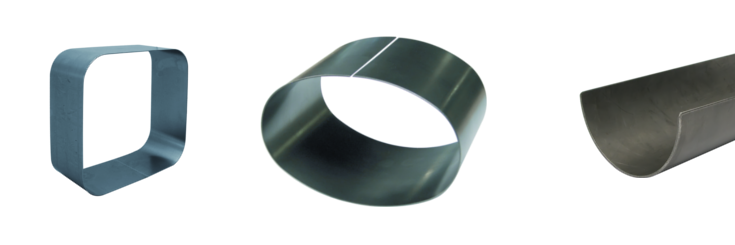

Example sizes RBA 42-120

|

|

|

||

|

Model

|

RBA 42

|

RBA 52

|

RBA 60

|

RBA 70

|

|

Effective length max [mm]

|

530

|

1030

|

1030

|

1030

|

|

Sheet thickness* max [mm]

|

1

|

1,2

|

1,5

|

1,8

|

|

Diameter upper roll [mm]

|

42

|

52

|

60

|

70

|

|

|

|

|

|

|

|

Model

|

RBA 85

|

RBA 100

|

RBA 120

|

|

|

Effective length max [mm]

|

1530

|

1530

|

1030

|

|

|

Sheet thickness* max [mm]

|

2,5

|

2,4

|

4,5

|

|

|

Diameter upper roll [mm]

|

85

|

100

|

120

|

|

|

|

|

|

|

|

|

* The sheet thickness refers to a material with a tensile strenght of 400 N/mm² and an elastic limit of 250 N/mm²!

|

|

|||

|

|

||||